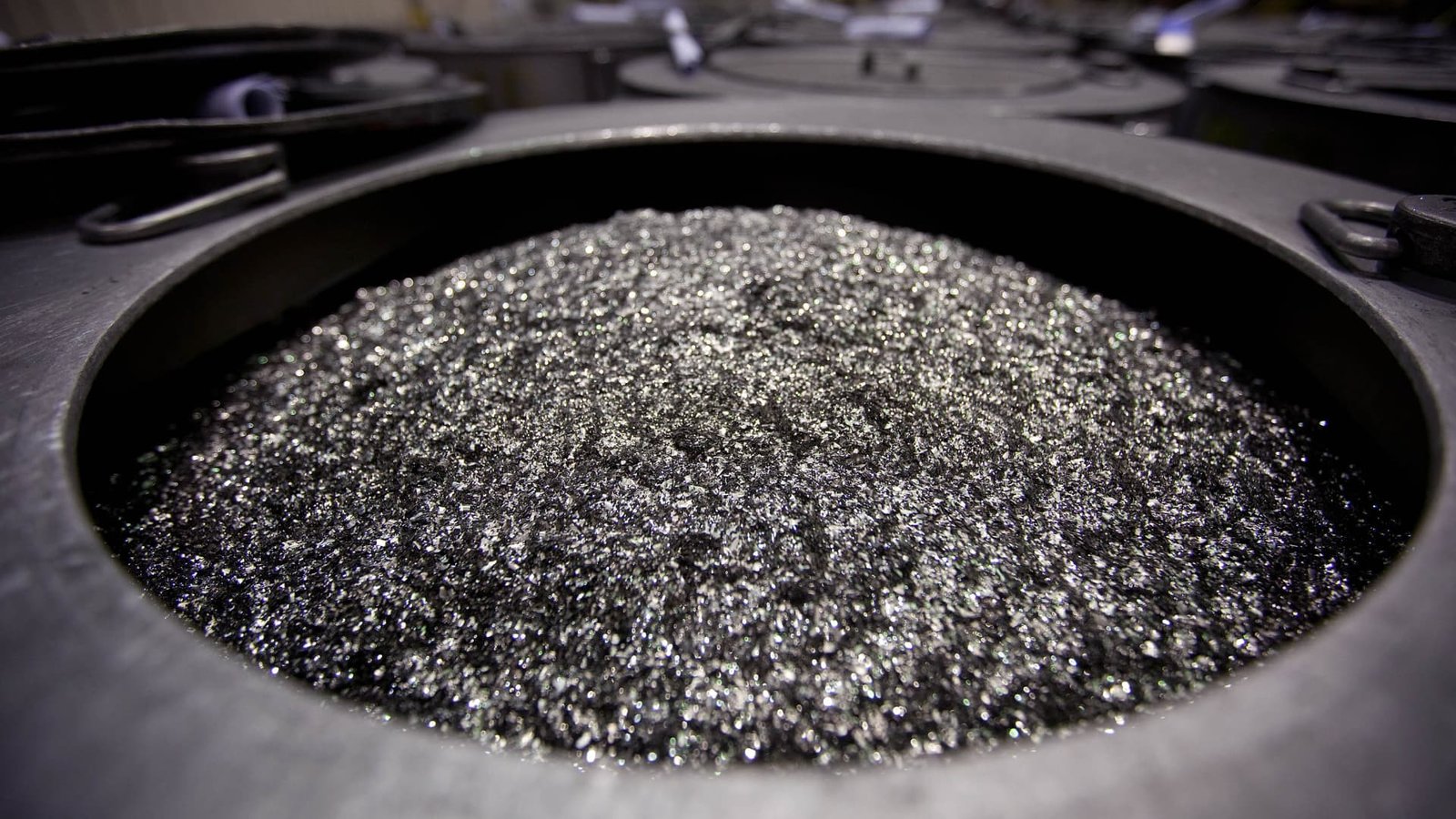

Annealed neodymium iron boron magnets sit in a barrel prior to being crushed into powder at Neo Material Technologies Inc.’s Magnequench Tianjin Co. factory in Tianjin, China.

Bloomberg | Bloomberg | Getty Images

BEIJING — As China tightens its grip on the global supply of key minerals, the West is working to reduce its dependence on Chinese rare earth.

This includes finding alternative sources of rare earth minerals, developing technologies to reduce reliance, and recovering existing stockpiles through recycling products that are reaching the end of their shelf life.

“You cannot build a modern car without rare earths,” said consulting firm AlixPartners, noting how Chinese companies have come to dominate the supply chain for the minerals.

In September 2024, the U.S. Department of Defense invested $4.2 million in Rare Earth Salts, a startup that aims to extract the oxides from domestic recycled products such as fluorescent light bulbs. Japan’s Toyota has also been investing in technologies to reduce the use of rare earth elements.

According to the U.S. Geological Survey, China controlled 69% of rare earth mine production in 2024, and nearly half of the world’s reserves.

Analysts from AlixPartners estimate that a typical single-motor battery electric vehicle includes around 550 grams (1.21 pounds) of components containing rare earths, unlike gasoline-powered cars, which only use 140 grams of rare earths, or about 5 ounces.

Pretty soon, the first generation of EVs will be up for recycling themselves, creating a pool of ex-China material that will be under the control of the West.

Christopher Ecclestone

Principal and mining strategist at Hallgarten & Company

More than half of the new passenger cars sold in China are battery-only and hybrid-powered cars, unlike the U.S., where they are still mostly gasoline-powered.

“With slowing EV uptake (in the U.S.) and mandates to convert from ICE to EV formats receding into the future, the imperative for replacing Chinese-sourced materials in EVs is declining,” said Christopher Ecclestone, principal and mining strategist at Hallgarten & Company.

“Pretty soon, the first generation of EVs will be up for recycling themselves, creating a pool of ex-China material that will be under the control of the West,” he said.

Only 7.5% of new U.S. vehicle sales in the first quarter were electric, a modest increase from a year ago, according to Cox Automotive. It pointed out that around two-thirds of EVs sold in the U.S. last year were assembled locally, but manufacturers still rely on imports for the parts.

“The current, full-blown trade war with China, the world’s leading supplier of EV battery materials, will distort the market even more.”